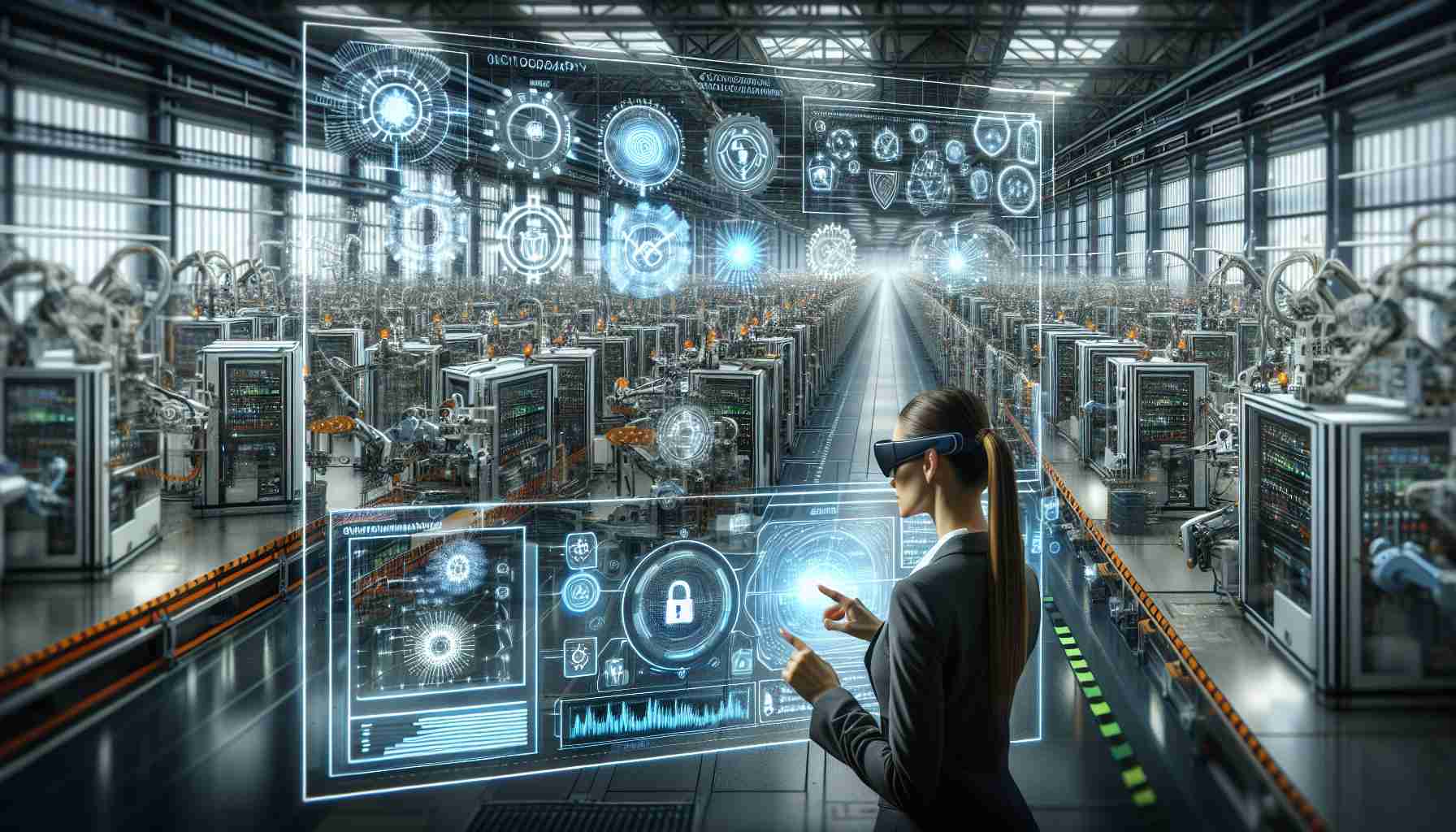

Smart manufacturing in the Asia-Pacific region presents numerous opportunities for growth and innovation, but it also comes with significant cybersecurity challenges that must be addressed. Embracing automation, robotics, and IoT technologies can revolutionize operational efficiency for manufacturers, yet it leaves them susceptible to cyberthreats. Cybersecurity expertise is in high demand as companies navigate the complexities of securing their networks and data.

As manufacturers integrate IT and OT networks, they face the risk of cyberattacks that could potentially disrupt operations on a large scale. Neglecting OT cybersecurity poses a severe threat, as demonstrated by incidents where industrial facilities were brought to a standstill due to cyber intrusions. The need for comprehensive cybersecurity measures cannot be overstated, especially as cybercriminals increasingly target the APAC manufacturing sector.

To fortify their defenses, manufacturers should adopt key strategies such as implementing a zero-trust approach, segmenting and hardening networks, deploying continuous monitoring, and developing an OT-specific incident response plan. These proactive measures can significantly reduce the likelihood and impact of cyber incidents, safeguarding smart manufacturing investments and ensuring continuity of operations.

In the face of evolving cyber threats, manufacturers must prioritize cybersecurity to protect their digital transformation initiatives and secure their position in the global market. By taking proactive steps to address vulnerabilities and strengthen infrastructure security, manufacturers can build a resilient cybersecurity posture that safeguards against potential cyber risks.

FAQ Section:

1. What are some of the opportunities associated with smart manufacturing in the Asia-Pacific region?

– Smart manufacturing in the Asia-Pacific region offers opportunities for growth and innovation through the integration of automation, robotics, and IoT technologies to enhance operational efficiency for manufacturers.

2. What are the significant cybersecurity challenges faced by manufacturers in smart manufacturing?

– Manufacturers embracing smart manufacturing face cybersecurity challenges due to the increased risk of cyberthreats as they integrate IT and OT networks, leading to potential disruptions in operations.

3. Why is OT cybersecurity crucial for manufacturers in the Asia-Pacific region?

– Neglecting OT cybersecurity poses a severe threat to manufacturers as incidents of cyber intrusions could bring industrial facilities to a standstill, emphasizing the need for comprehensive cybersecurity measures.

4. What strategies should manufacturers adopt to enhance cybersecurity in smart manufacturing?

– To strengthen defenses against cyber incidents, manufacturers should consider implementing a zero-trust approach, network segmentation, continuous monitoring, and developing an OT-specific incident response plan.

5. How can manufacturers protect their digital transformation initiatives from cyber threats?

– By prioritizing cybersecurity, taking proactive steps to address vulnerabilities, and enhancing infrastructure security, manufacturers can build a resilient cybersecurity posture that safeguards against evolving cyber risks.

Key Terms/Jargon:

1. IT: Stands for Information Technology, referring to the use of computers and technology to manage and process information.

2. OT: Operational Technology is hardware and software used to monitor, control, and manage industrial operations.

3. IoT: Internet of Things represents a network of interconnected devices that can communicate and share data with each other.

Suggested Related Links:

– exampledomain.com